Automated manufacturing operations depend on sensor equipment to make sure each step of the process is completed reliably and effectively. For many applications, inductive sensors can do a fine job of monitoring and maintaining the automated manufacturing process. When working with glass or transparent polymers, however, you need a different type of sensor. In this… Read more »

Author: Locon Sensor Systems Inc

Did You Know We Also Offer Safety Light Curtains?

In this blog, we typically focus on sensor products that make automated processes more accurate, more reliable and more efficient. These sensors come in a wide variety of different configurations, and they have applications in everything from food processing to vehicle manufacturing. But did you know that in addition to these products, we also carry… Read more »

New User-Friendly Functionality Coming to Locon’s Website

Here at Locon, we’ve developed an extensive line of sensor equipment to accommodate the needs of customers in a wide variety of industries. From extended temperature models to machine vision sensors and even custom designed options, we make sensors for just about every application you can think of. With all those different options available, we… Read more »

Standard Inductive Sensor Options Offer Affordable Reliability

Recently, we’ve highlighted a number of the more specialized sensor options you can find at Locon on our blog. These include miniature sensor units for applications with extreme space restrictions, and high temperature sensors for harsh operating environments. These specialized sensors might be ideal in some cases, but they’re not always necessary. For applications that… Read more »

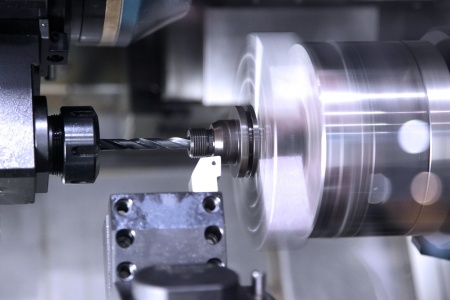

No Space is Too Small for These Miniature Sensor Units

Even the largest manufacturing plants rely on small, specialized machines to function effectively. In fact, the more complex your operation becomes, the more likely you are to struggle with size and space restrictions. Tool and die makers, CNC machines and advanced robotics are especially prone to these limitations. Fortunately, we have a number of types… Read more »

Understanding Your High Temperature Inductive Sensor Options

High temperature inductive sensors are designed and built to operate effectively in extremely harsh environments. These sensors are widely employed in places like foundries, forges, and factories that use plastic injection molds. They must deliver consistent performance across a wide temperature range, and stand up to the wear and tear associated with these extreme… Read more »

Washdown Sensors Ideal for Food Processing Operations

Sensing equipment in food processing plants must not only be precise and reliable, but also designed with the rigorous cleaning requirements associated with food safety guidelines in mind as well. For these applications, we recommend durable food-grade washdown inductive sensors. These sensors offer food processing operations a number of key benefits specific to their industry…. Read more »

Photoelectric Sensors Facilitate Automated Quality Control

Modern process plants are fast-paced, highly automated operations that require a great deal of precision to perform properly. Take food packaging, for example. This process is broken down into a series of discreet steps, each of which much be accomplished reliably and efficiently so that subsequent steps can be completed in turn. This type of… Read more »

How Inductive Sensors Help Vehicle Manufacturers

Sensors continue to make a dynamic impact on the world around us, as they’re used in a variety of ways. For instance, a manufacturer of utility vehicles uses inductive sensing to identify the model of each chassis as it’s received in their local body shop. A utility vehicle is lifted onto the line using pulleys… Read more »

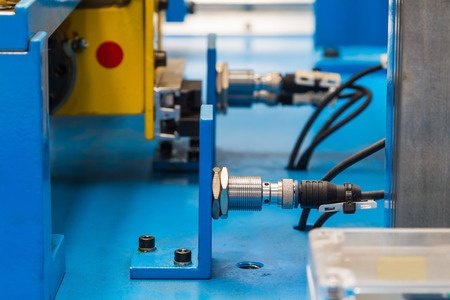

Reduce Setup Times With Inductive Proximity Sensors

To make certain of tool closure, it’s a good idea to utilize inductive proximity sensors. When machinery is operating, you want it to work flawlessly so you don’t have any downtime, mistakes, or problems. Inductive proximity sensors help to ensure a tool-press is completely closed before molding tools are changed. The sensors monitor the machinery… Read more »